For more than several decades, the Sigmaphi team has helped you to design, build, measure and install any system able to deviate particles : any size (from 1kg to 100 tons), any quantity (from a single unit to a serial production of 300 magnets), including any size of conductor or any specific enquiry (radiation resistance, extreme conditions…)

Pulsed

magnets

Our design capabilities

Our magnetic calculation experts will find the best solution for your project, optimized according to your principle needs (magnetic performance, dimensions, costs and energy consumption).

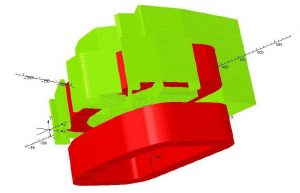

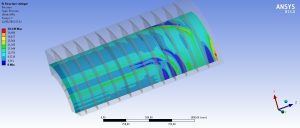

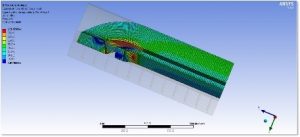

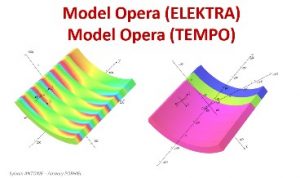

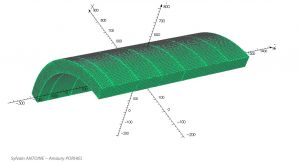

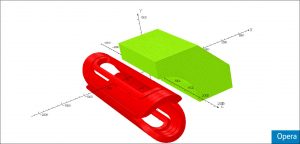

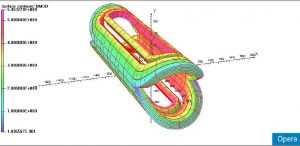

Our mechanical calculation tools enable us to design support stands, frames, and reinforcement structures. For our customers located in relevant areas, we are used to designing stands compliant with earthquake resistance standards. We design your magnet from A to Z: magnetism, mechanics, cryogenics, quench detection and calculation, thanks to our detailled knowledge of the best software : Opera, Ansys, Tosca, Elektra, Solidworks, Tempo, Quench, …

Ansys

Tempo (thermal stress calculation)

Solidworks (CAD-CAM and realization)

Opera (3D magnetic modelling)

We have a globally acknowledged expertise in magnetic measurement

Our magnetic measurements team, experts with a worldwide reputation, will prepare your program with you. This will allow us to specifically design your product. You will be welcome to be present during the measurements. Do you need a new measurement system? We can carry out your project and supply a complete solution from A to Z

We design and manufacture our own measurement equipment (rotating coils, calibration magnets, mapping systems, acquisition systems) and can supply you with tailor-made equipment.

Manufacturing

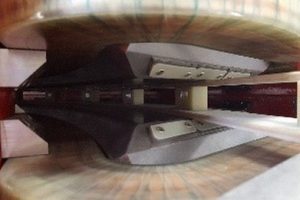

Winding/integration

Every day, our team manufacture tens of coils in our winding and vacuum impregnation workshops, without compromising on quality.

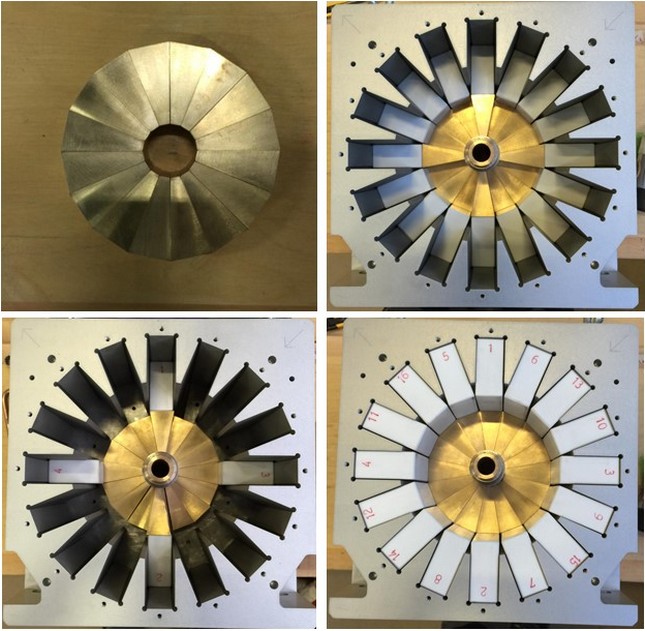

Stacking/Welding

With several decades of know-how behind us, we are able to reach 30µm accuracy on our stacked yokes, without any further machining.

We handle several type of welding: TIG, MIG…

Assembly

Our skilled and experienced workers use all the necessary care for assembly , especially for the most difficult items.

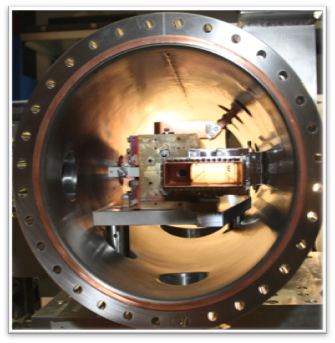

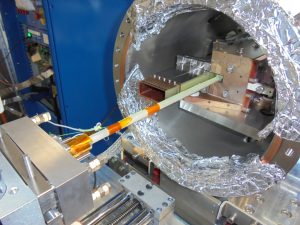

Vacuum and ultra-high vacuum assembly

We have a dedicated workshop and team for ultra-high vacuum activities, including all necessary equipment to test our products :

Helium leak test detector (up to 1.0 E-12 mbar.l/s)